A half-cut solar panel is a modern-day technology that helps in enhancing solar power energy. These panels decrease the cell size to accommodate more cells in the system.

This technology has an improved design and consists of an anti-reflective coating or anti-reflective glass, printed silver paste (front contact), back surface field, a doped semiconductor, and printed aluminium paste (rear connection).

These components make the Half-cut solar panels more reliable and efficient than conventional models.

How Do Half-Cut Solar Panels Work?

A half-cut solar panel works more effectively than traditional solar panel systems. In previous models, the solar panels contained 0.5V solar cells. These were combined and placed in a series. Then when the voltage was added, the cells operated at 30 V.

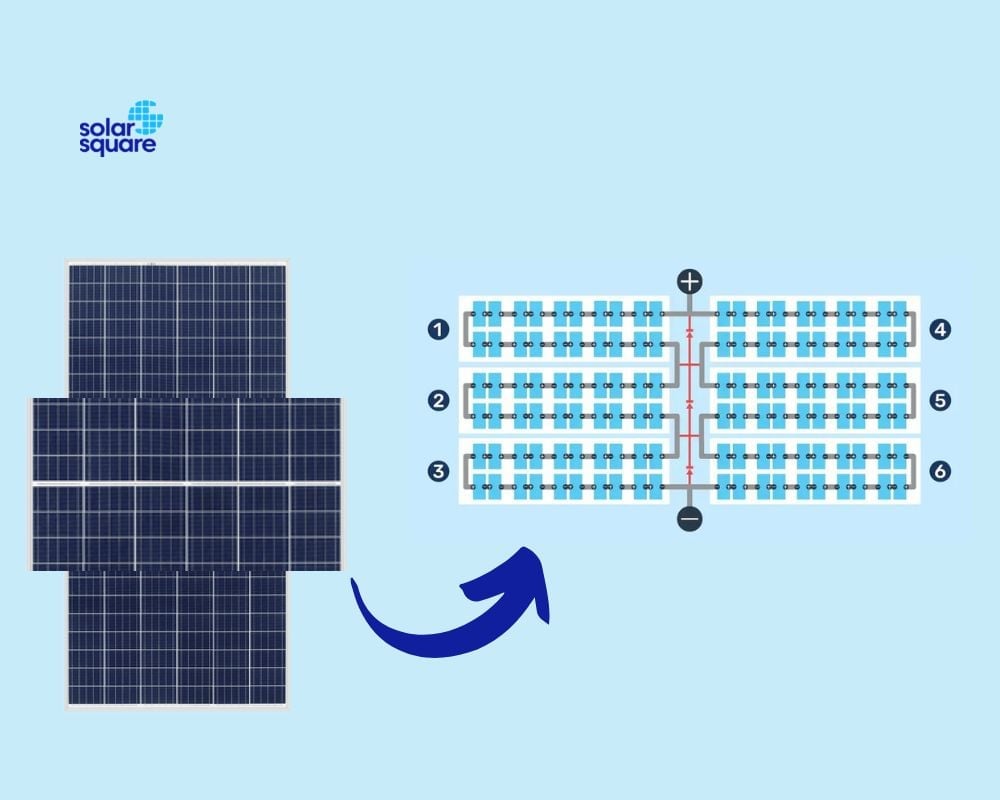

But in half-cut solar panels, the solar cells are cut using a laser cutter and then added to the series. Although this process reduces the power output, the voltage stays unaffected.

Moreover, the voltage power doubles when new half-cut cells are included in the series. Hence, compared to conventional solar cells, these offer enhanced electricity and better functionality for a long time.

The Efficiency Of Half-Cut Solar Panels

Half-cut solar panels are far more efficient and operate better than conventional ones. They have 120 to 144 cells that are almost double the cells in the monocrystalline solar panels.

These solar panels are made from the passivated emitter and rear cell (PERC) technology and provide high module efficiency.

Besides, in half-cut solar panels, no heavy resistive losses occur. Since the cells are cut into halves, the energy transmission from the wire to the household appliances becomes slow. Therefore, the power loss is much slower.

Additionally, the half-cut solar panels have high shade tolerance, unlike the conventional models.

In traditional models, the solar panel system stopped working if a row was shaded. But since half-cut solar panels have a different wiring arrangement, the power production does not stop if one row is shaded.

All these features make half-cut solar panels better in performance than conventional solar panels.

Pros And Cons Of Buying A Half-Cut Solar Panel

Half-cut solar panels are excellent for elevating the solar panel system’s energy yield. Yet, there are many advantages and some disadvantages of buying a half-cut solar panel. Find the details below.

Advantages of buying a half-cut solar panel

- There are fewer chances of power loss.

- It offers high shade tolerance.

- The half-cut solar panels provide increased low-light performance.

- The cells are compact and less prone to cracks.

- It features the latest solar design.

- It minimises the temperature of hot spots.

- It provides low electrical resistance.

- It is made of high-quality, durable materials.

- It has high longevity.

Disadvantages of buying a half-cut solar panel:

- It is expensive.

- There is a possibility of soldering.

- The cells can cause internal dysfunctioning after cutting.

Cost Of a Half-Cut Solar Panel

The cost of a halfcut solar panel is approximately Rs. 8800 per piece for 400 W. Please note, the price can differ depending on the power capacity.

The higher the voltage, the more will be the price of half-cut solar panels. Similarly, the durability and space required for installation are the other two factors affecting the total cost of a half-cut solar panel.

Generally, these panels are more expensive than the traditional ones as double the average number of cells are required to make them. Besides, the manufacturing cost also adds to the total price, making it costlier than other solar panels.

Subsidies For Half-Cut Solar Panels

As of now, the Indian government offers subsidies for DCR panels only. Since most Indian manufacturers are able to produce only polycrystalline solar panels single-handedly, the current subsidy schemes are curtailed to polycrystalline solar panels only.

Thus, there’s no subsidy provided for half-cut solar panels in India as of now.

Maintenance Of A Half-Cut Solar Panel

Regular maintenance is essential to keep the half-cut solar panels working for a long time and avoid malfunctioning. Follow the tips below to remove the grime and dirt on the solar panels that accumulate over time.

- Use a sponge and brushes to remove the dirt on the surface. Homeowners can clean the panels using a garden hose.

- Apply a cleaning agent to the brushes to wipe the grime.

- It is essential to check the condition of the solar panel after every three months to see if all the parts are working fine. If required, replacement of the components must be done.

Conclusion

The half-cut solar panels have improved the overall output of solar energy. Though challenging to manufacture, this innovative technology provides better performance for an extended period.

These solar panel systems adhere to modern-day requirements and are more efficient than traditional solar panel versions. Homeowners can purchase this device, install it on the roof, and save electricity costs to a great extent.

FAQs

1. Do solar panels get damaged when they are cut in half?

No, the solar panels do not get damaged when they are cut in half. However, doing so can reduce the current flow. But the voltage stays the same even after cutting.

2. Do half-cut solar panels have small cells?

Yes, half-cut solar panels have small cells. Since the panels are cut into two halves, the average size of the solar cell gets split, resulting in a reduced size.

3. Can half-cut solar panels break?

Half-cut solar panels are pretty durable and do not break under normal conditions. However, environmental changes like hail storms and water accumulation during the rainy season can damage the solar power system.